Products

Silicon Steel Wound Core

Transformer Silicon Wound Core

- Detail

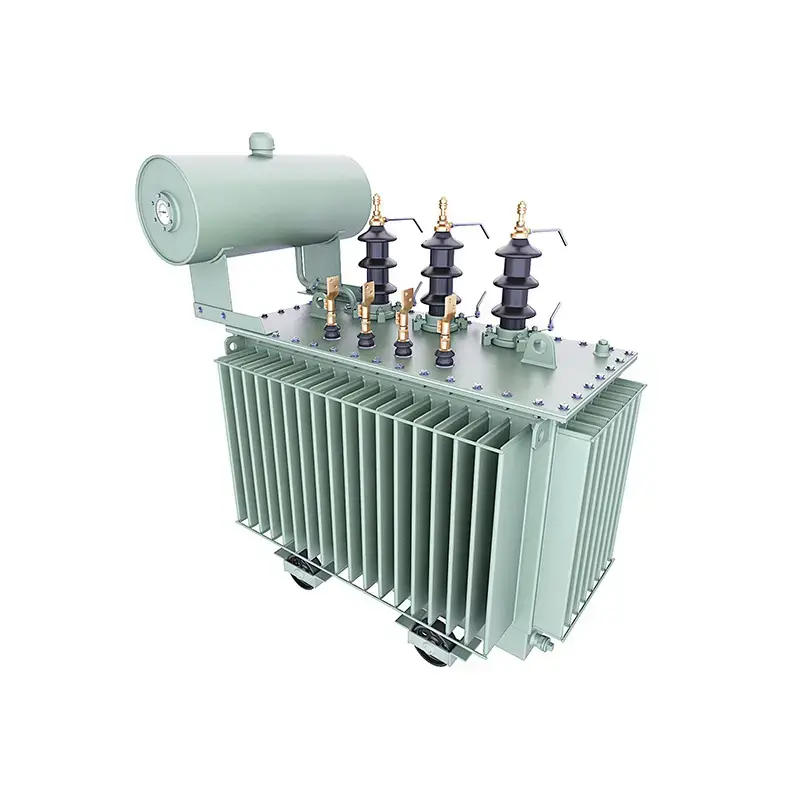

In electrical engineering, the transformer core plays a critical role in the efficient operation of power transformers. As a key component, the transformer core is designed to facilitate the transfer of electrical energy between circuits while minimizing energy losses.

Wide Range Of Specifications

Transformer cores are available in a variety of sizes to meet various power requirements. From 5kVA to 100MVA, these cores are carefully designed to meet the needs of different applications, allowing you to choose the right transformer core for your specific needs, whether it is a small operation or a large industrial application.

High-Quality Materials

The performance of a transformer core is significantly influenced by its construction materials. High-quality, low-iron-loss, high-permeability cold-rolled grain-oriented silicon steel (CRGO) is the preferred material for transformer cores. This specialty steel is available in a variety of thicknesses, including 0.23 mm, 0.27 mm, 0.30 mm, 0.35 mm, and 0.5 mm. The use of laser-coated CRGO, a unique electrical silicon steel, can further enhance the efficiency of power transformers. These materials are specifically designed to minimize energy losses and enhance the overall performance of the transformer.

Innovative Design Features

A key feature of the transformer core is its innovative design. The two halves of the core are closed together to form an open structure with a closed magnetic circuit. This design not only optimizes the magnetic flux but also allows the coil and core to be produced separately. The easy assembly feature shortens the total production time and improves production efficiency. It can maintain high quality standards while simplifying the operation process.

Multi-Functional Applications

Transformer cores are suitable for a variety of power transformers, with widespread use in 50Hz and 400Hz transformers. Their applications extend beyond traditional power transformers to include current transformers, reactors, chokes, and other magnetic components in electronic equipment. This versatility makes transformer cores an essential component across a wide range of industries, including power generation, telecommunications, and manufacturing.

Custom Design Options

Transformer cores offer custom design options, allowing customers to tailor core specifications to their needs. This flexibility ensures businesses can achieve optimal performance and efficiency for their electrical systems.

Commitment To Quality And Reputation

At the heart of transformer core manufacturing is a commitment to quality and integrity. NATEN is dedicated to providing products that not only meet but also exceed industry standards. By focusing on high-quality materials, innovative designs, and customizable options, we ensure reliable performance and a long service life for our transformer cores.

Transformer cores are essential for the proper functioning of power transformers and other magnetic components. With a comprehensive range of specifications, high-quality materials, innovative designs, and a wide range of applications, transformer cores are crucial for efficient energy transmission across a wide range of industries. NATEN's continued emphasis on quality and customization ensures a bright future for transformer cores, paving the way for advancements in electrical engineering and technology.

Production pictures

Production line pictures

Package & Shipping

We have been in all kinds of steel, which can meet your various needs. At the same time, we have good cooperation with China each big steel companies , our company is reliable.