Products

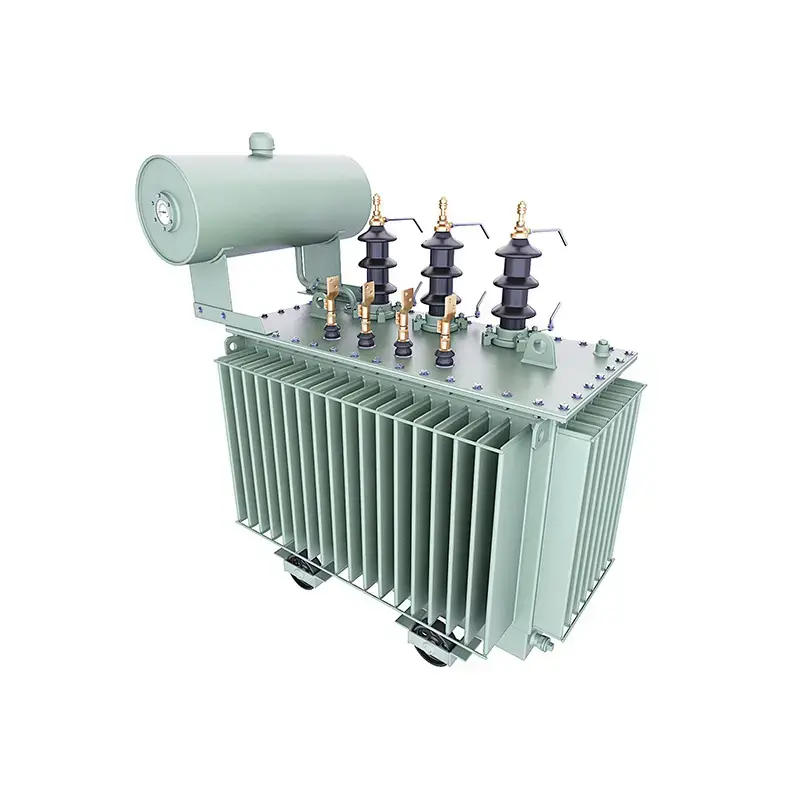

Pole Mounted Transformer

Single Phase Overhead Distribution Pole Mounted Transformer

- Detail

- Technical Parameters

The Naten overhead transformer may be used alone for the supply of a single phase load or as one of three units in a bank for the supply of a three phase load.

General

The unit may be direct mounted to a wooden or concrete pole, or cluster mounted on a pole for three phase use. Our single phase overhead distribution transformer is commonly used in various places including rural areas, remote regions and scattered villages to provide high quality power supply for daily lighting, agricultural production and industrial plants. Aside from these, it is also suitable for the energy saving projects for railway and urban grid.

Product Standards

●IEEE Std C57.12.00™-2000 standard – IEEE Standard for Standard General Requirements for Liquid-Immersed Distribution, Power, and Regulating Transformers.

●IEEE Std C57.12.20™-2005 standard – IEEE Standard for Overhead-Type Distribution Transformers, 500kVA and Smaller: High Voltage, 34500V and Below; Low Voltage, 7970/13800Y V and below.

●IEEE Std C57.12.31™-2010 standard – IEEE Standard for Pole Mounted Equipment – Enclosure Integrity.

●IEEE Std C57.12.35™-1996 standard – IEEE Standard for Bar Coding for Distribution Transformers.

●IEEE Std C57.12.90™-2006 standard – IEEE Standard Test Code for Liquid-Immersed Distribution, Power, and Regulating Transformers.

●IEEE Std C57.12.91™-2001 standard – IEEE Guide for Loading Mineral-Oil-Immersed Transformers.

●NEMA TR 1-1993 (R2000) Elevated Temperatures.

(ASTM)American Society for Testing Materials

Main Features

●Type: Conventional or CSP type

●Suitable for both indoor or outdoor

●Ambient temp: -25℃-+40℃

●Winding temp rise : 55 ℃ or 65 ℃

●Core: CRGO or Amorphous Core

●Efficiency standard: DOE 2016 or NEMA TP1

●Winding material : CU or AL

●Frequency: 50HZ or 60HZ

●Capacity : 5kVA to 333kVA

Quality Assurance

Naten Quality assurance is an integral part of the process.All electrical testing is per IEEE standards.Quality of processed parts and subassemblies are the responsibility of the production personnel.Regular quality inspections and spot checking are conducted to make sure that good and consistent quality is achieved and maintained.

Routine Tests

●In-process Core Loss Test

●Transformer Turns Ratio Test

●Winding Resistance Test

●Polarity and Phase Displacement Test

●Insulation Power Factor Test

●Liquid Insulation DBV Test

●No Load Loss & Excitation Test

●Impedance Voltage & Load Loss Test

●Voltage Ratio Test

●Applied Potential Test

●Induced Potential Test

Type Tests

●Temperature Rise Test

●Basic Impulse Level (BIL)

●Sound Level test

Production

Product Design

|

Table of Liquid Single phase pole mounted transformer (<150kV BIL) Temp rise 65℃ |

||||||||

|

kVA |

Primary voltage |

Secondary voltage |

A mm |

B mm |

C mm |

Weight (kG) |

Efficiency % |

|

|

DOE2016 |

NEMA TP1 |

|||||||

|

10 |

4160 7200 7620 12470 13200 13800 24940 19920 |

120/240 240/480 277 346 600 |

530 |

600 |

1060 |

160 |

98.70% |

98.40% |

|

15 |

530 |

600 |

1060 |

180 |

98.82% |

98.60% |

||

|

25 |

580 |

660 |

1080 |

230 |

98.95% |

98.70% |

||

|

37.5 |

610 |

690 |

1090 |

290 |

99.05% |

98.80% |

||

|

50 |

650 |

700 |

1100 |

340 |

99.11% |

98.90% |

||

|

75 |

680 |

750 |

1250 |

450 |

99.19% |

99.00% |

||

|

100 |

730 |

800 |

1250 |

500 |

99.25% |

99.00% |

||

|

167 |

900 |

850 |

1300 |

780 |

99.33% |

99.10% |

||

|

250 |

1200 |

900 |

1450 |

1100 |

99.39% |

99.20% |

||

|

333 |

1350 |

1200 |

1500 |

1300 |

99.43% |

99.20% |

||