Products

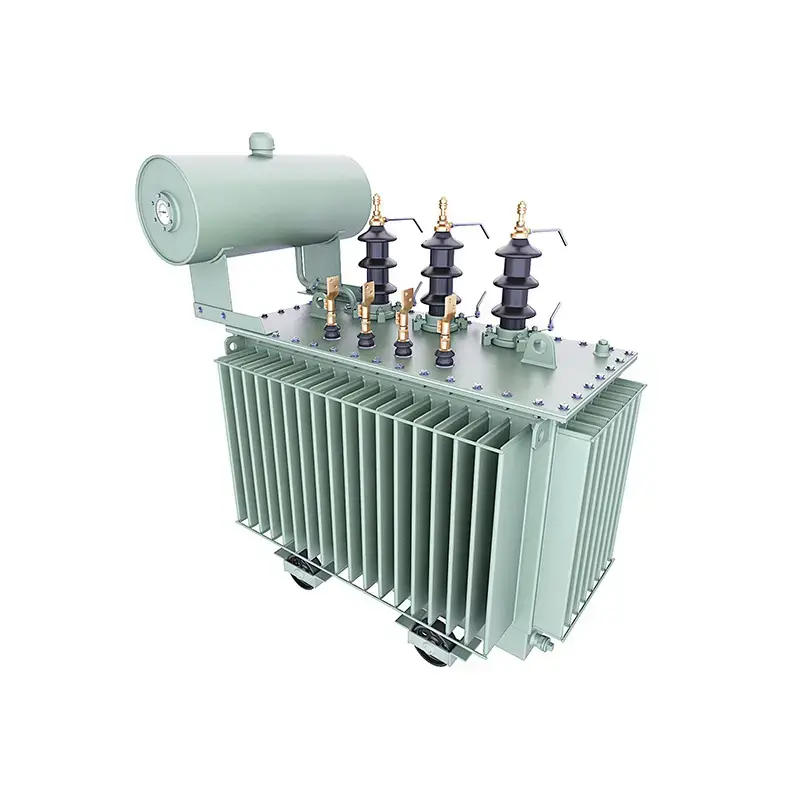

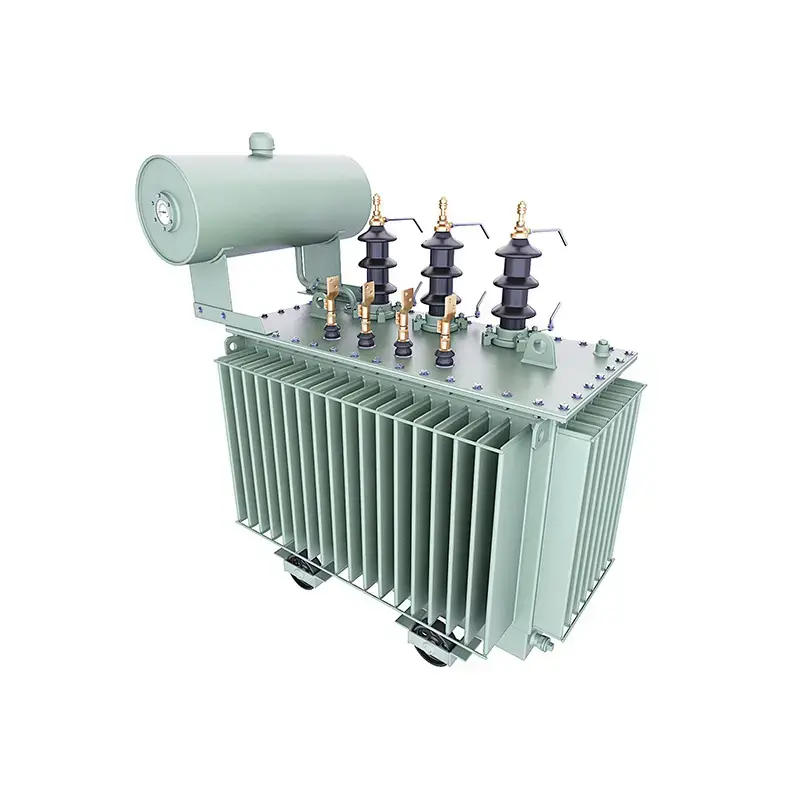

Oil Immersed Transformer

Three Phase Oil Immersed Distribution Transformer

- Detail

- Technical Parameters

Naten offers a complete range of distribution transformers designed to grant the reliability, durability, and efficiency required in utility, industrial, and commercial applications.

General

Naten's liquid-filled transformers are manufactured in accordance with the most demanding industry and international standards. Compliance with important standards, from IEC to VDE, is a matter of course, just as much as the exclusive use of high-quality materials, qualified employees implement the demanding standards in daily practice.

Standard Features

1.Product Range:15kVA-10000kVA, up to 44kV

2.System voltage: max. 36 kVA 200 BIL

3.Coolers: corrugated wall or radiator

4.Oil preservation: hermetically sealed or conservator/free breathing

5.Tap changer: off-circuit or on-load

6.Cooling medium: mineral oil, Midel

7.Steel type core clamping system

8.High voltage (HV) multilayer winding

9.Low voltage (LV) foil winding or layer winding

10.Winding materials aluminium or copper

11.High temperature class transformers

12.Low noise solution

13.Efficient transformers with reduced losses

14.Liquid-filled

15.Used in special conditions

16.Sophisticated facilities

17.Usage of wooden case

18.3D package for drawings

19.Special test like Zero Sequence Impendence test

20.Cooling: ONAN, ONAN/ONAF, KFAF, KFW

Service Condition

a) Suitable for indoor or outdoor application.

b)Air temperature: Maximum temperature: +40℃; Minimum temperature:-30℃.

c) Humidity:Monthly average humidity 95%;Daily average humidity 90%.

d) Altitude above sea level:

Maximum installation altitude:2000m

e)Max wind speed:35M/s

f) Ambient air not apparently polluted by corrosive and flammable gas, vapor etc.

g) No frequent violent shake.

Note: * Beyond those services condition should enquiry to manufacturer technical dept during order.

Tests

●Voltage ratio. Polarity and phase relationship test on each tapping

●Resistance of all windings

●No-load current and no-load losses measurement

●Load losses measurement at rated current and frequency

●Impedance voltage measurement

●Induced over-voltage and separate source voltage withstand tests

●Impulse voltage withstand test

●Noise level test

●Oil leakage test

●Overload test at 150% rated current for one hour after temperature rise test and hot resistance measurement of (HV - LV)

Custom Work- In Macrocosm And In Microcosm

1. THE IRON CORE

Whether in design, manufacturing methods or materials the cores of Naten transformers represent the latest state of technology.The silicon alloyed electric sheet steel used is grain-oriented, cold-rolled and insulated on both sides, guaranteeing low losses and noise and these values are even improved by laser treatment. Numerically controlled cutting machines provide for careful treatment in the cutting process in order to avoid mechanical tension in the core and thus unwanted properties right from the beginning. Standard use of step-lap cutting additionally minimizes losses and noise.

2.THE WINDING

The winding as the centerpiece of the transformer must be especially protected -both against high electrical stress due to external over voltages and against mechanical overloads by short circuits. Naten transformers are systematically designed to meet these requirements. The windings are made of copper or aluminum.Low-voltage windings are made of strip or flat wire, and the high voltage windings are manufactured from round or profile wire. The use of insulating paper that is partially coated with epoxy resin ("diamond-dotted paper") bonds the winding into a compact block while drying and increases the short-circuit capacity additionally.

3.THE TANK

Whether during transport or operation -the tank must be absolutely tight under mechanical stress. Preconditions to achieve this are constructional experience, the most modern calculation methods and high-quality welding work. Special attention is paid to corrosion protection. Pretreatment of the surface bysandblasting contributes to corrosion protection, just like multi coating with preset drying times for each layer. On request, hot-dip galvanization provides for even better protection. The tank must dissipate the entire heat loss of the transformer into the ambient air. This makes the volume of the transformer fluid change. In hermetically sealed transformers, the corrugated walls absorb the change in volume. In the case of expansion tank transformers, the conservator compensates this change. The sheet-steel lids of Naten transformers are bolted together with the tank or welded on request. In any case the steel thickness and the bracing is dimensioned in such a way that the lid withstands the stress of transport and operation.

11KV Series

|

KVA |

VOLTAGE |

VECTOR GROUP |

LOSSES |

NO-LOAD CURRENT |

WEIGHT(KG) |

OVERALL DIMENSION MM |

|||||

|

|

H.V KV |

L.V V |

NO-LOAD LOSS |

LOAD LOSS |

OIL WEIGHT |

TOTAL WEIGHT |

L |

W |

H |

||

|

25 |

6 6.3 10 10.5 11 13.2 |

380 400 415 433 |

YYNO DYN11 YZN11 |

100 |

550 |

2.3 |

55 |

230 |

720 |

440 |

855 |

|

30 |

130 |

630 |

2.1 |

75 |

305 |

750 |

500 |

990 |

|||

|

50 |

170 |

910 |

2.0 |

80 |

405 |

800 |

480 |

1030 |

|||

|

63 |

200 |

1090 |

1.9 |

95 |

455 |

830 |

615 |

1060 |

|||

|

80 |

240 |

1310 |

1.9 |

105 |

510 |

840 |

580 |

1115 |

|||

|

100 |

290 |

1580 |

1.8 |

120 |

530 |

890 |

645 |

1145 |

|||

|

125 |

340 |

1890 |

1.7 |

130 |

670 |

910 |

600 |

1185 |

|||

|

160 |

400 |

2310 |

1.6 |

140 |

810 |

910 |

700 |

1280 |

|||

|

200 |

480 |

2730 |

1.5 |

160 |

890 |

1000 |

760 |

1240 |

|||

|

250 |

560 |

3200 |

1.4 |

175 |

1020 |

1285 |

730 |

1290 |

|||

|

315 |

670 |

3830 |

1.4 |

185 |

1170 |

1280 |

740 |

1385 |

|||

|

400 |

800 |

4520 |

1.3 |

215 |

1410 |

1310 |

750 |

1432 |

|||

|

500 |

960 |

5410 |

1.2 |

260 |

1645 |

1365 |

765 |

1510 |

|||

|

630 |

1200 |

6200 |

1.1 |

310 |

2070 |

1485 |

815 |

1615 |

|||

|

800 |

1400 |

7500 |

1.0 |

370 |

2445 |

1640 |

930 |

1590 |

|||

|

1000 |

1700 |

10300 |

1.0 |

425 |

2800 |

1860 |

1120 |

1630 |

|||

|

1250 |

1950 |

12000 |

0.9 |

480 |

3320 |

1860 |

1120 |

1830 |

|||

|

1600 |

2400 |

14500 |

0.8 |

550 |

4175 |

1975 |

1175 |

1900 |

|||

NOTE: *The above parameter is only subject to our standard.

Design, special requirement can be customized.

22KV Series

|

KVA |

VOLTAGE |

VECTOR GROUP |

LOSSES |

NO-LOAD CURRENT |

WEIGHT(KG) |

OVERALL DIMENSION MM |

|||||

|

|

H.V KV |

L.V V |

NO-LOAD LOSS |

LOAD LOSS |

OIL WEIGHT |

TOTAL WEIGHT |

L |

W |

H |

||

|

25 |

20 22 24 |

380 400 415 433 |

YYN0 DYN11 YZN11 |

120 |

590 |

2.3 |

75 |

230 |

880 |

610 |

855 |

|

30 |

135 |

750 |

2.1 |

100 |

305 |

900 |

610 |

990 |

|||

|

50 |

175 |

1050 |

2.0 |

185 |

515 |

920 |

610 |

1150 |

|||

|

63 |

200 |

1260 |

1.9 |

195 |

550 |

920 |

630 |

1180 |

|||

|

80 |

240 |

1510 |

1.9 |

200 |

600 |

930 |

650 |

1200 |

|||

|

100 |

265 |

1820 |

1.8 |

210 |

695 |

950 |

680 |

1250 |

|||

|

125 |

320 |

2180 |

1.7 |

235 |

810 |

960 |

780 |

1270 |

|||

|

160 |

370 |

2670 |

1.6 |

255 |

950 |

1160 |

710 |

1330 |

|||

|

200 |

450 |

3150 |

1.5 |

280 |

1065 |

1190 |

730 |

1340 |

|||

|

250 |

530 |

3690 |

1.4 |

300 |

1200 |

1280 |

820 |

1360 |

|||

|

315 |

635 |

4410 |

1.4 |

320 |

1360 |

1380 |

910 |

1390 |

|||

|

400 |

755 |

5200 |

1.3 |

370 |

1580 |

1430 |

950 |

1470 |

|||

|

500 |

900 |

6220 |

1.2 |

400 |

1790 |

1520 |

1020 |

1510 |

|||

|

630 |

1070 |

7500 |

1.1 |

460 |

2100 |

1680 |

1150 |

1530 |

|||

|

800 |

1295 |

9075 |

1.0 |

495 |

2420 |

1810 |

1280 |

1580 |

|||

|

1000 |

1520 |

12460 |

1.0 |

590 |

3080 |

1840 |

1290 |

1690 |

|||

|

1250 |

1800 |

14540 |

0.9 |

630 |

3460 |

1850 |

1300 |

1730 |

|||

|

1600 |

2170 |

17545 |

0.8 |

710 |

4015 |

1920 |

1350 |

1790 |

|||

NOTE: *The above parameter is only subject to our standard.

Design, special requirement can be customized.

33KV Series

|

KVA |

VOLTAGE |

VECTOR GROUP |

LOSSES |

NO-LOAD CURRENT |

WEIGHT(KG) |

OVERALL DIMENSION MM |

|||||

|

|

H.V KV |

L.V V |

NO-LOAD LOSS |

LOAD LOSS |

OIL WEIGHT |

TOTAL WEIGHT |

L |

W |

H |

||

|

25 |

30 30.8 33 35 38.5 |

380 400 415 433 |

YYN0 DYN11 YZN11 |

90 |

800 |

2.3 |

185 |

540 |

720 |

900 |

1200 |

|

30 |

100 |

1000 |

2.1 |

190 |

550 |

880 |

900 |

1200 |

|||

|

50 |

210 |

1270 |

2.0 |

205 |

590 |

900 |

950 |

1450 |

|||

|

63 |

230 |

1500 |

1.9 |

210 |

620 |

1000 |

950 |

1500 |

|||

|

80 |

250 |

1750 |

1.9 |

225 |

660 |

1020 |

970 |

1550 |

|||

|

100 |

290 |

2120 |

1.8 |

240 |

790 |

1050 |

1000 |

1600 |

|||

|

125 |

340 |

2500 |

1.7 |

270 |

950 |

1080 |

1030 |

1630 |

|||

|

160 |

360 |

2970 |

1.6 |

285 |

1020 |

1100 |

1060 |

1630 |

|||

|

200 |

430 |

3500 |

1.5 |

325 |

1170 |

1130 |

1060 |

1670 |

|||

|

250 |

510 |

4160 |

1.4 |

340 |

1340 |

1190 |

1160 |

1700 |

|||

|

315 |

610 |

5010 |

1.4 |

400 |

1530 |

1260 |

1240 |

1790 |

|||

|

400 |

730 |

6050 |

1.3 |

490 |

1780 |

1280 |

880 |

1900 |

|||

|

500 |

860 |

7280 |

1.2 |

510 |

1960 |

1960 |

940 |

1920 |

|||

|

630 |

1040 |

8280 |

1.1 |

600 |

2290 |

2020 |

1010 |

2010 |

|||

|

800 |

1230 |

9900 |

1.0 |

660 |

2640 |

2070 |

1040 |

2150 |

|||

|

1000 |

1440 |

12150 |

1.0 |

735 |

3100 |

2240 |

1200 |

2150 |

|||

|

1250 |

1760 |

14670 |

0.9 |

830 |

3630 |

2300 |

1280 |

2250 |

|||

|

1600 |

2120 |

17550 |

0.8 |

935 |

4235 |

2450 |

1510 |

2350 |

|||

NOTE: *The above parameter is only subject to our standard.

Design, special requirement can be customized.