Products

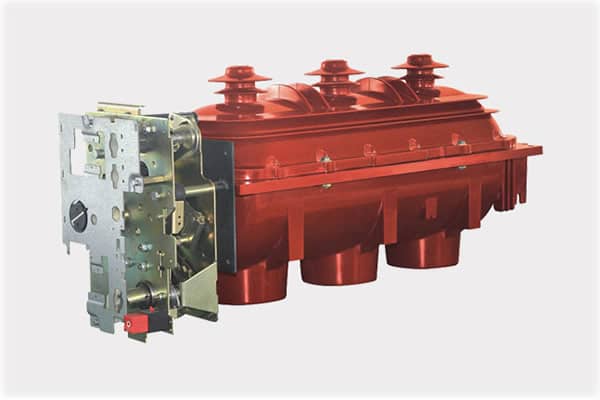

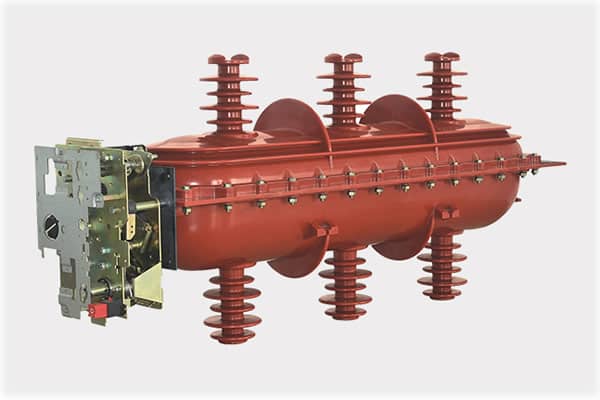

SF6 Load Break Switch

Key Features

whole solution for load break switch(switch disconnector) 12kV,24kV,36kV. Naten Electric manufactures high quality indoor SF6 load break switch which is used in gas insulated switchgear and ring main unit (RMU). Contact for a low price.

whole solution for load break switch(switch disconnector) 12kV,24kV,36kV

Load break switch compartment

Load break switch plus fuse combination compartment.

Upper Load break switch compartment

Lower Load break switch compartment.

RLS-12/24/36 an indoor high-voltage SF6 load switch, an switchgear with the rated voltage of 12kV/24kV/36kV, adopted with SF6 gas as an arc-extinguishing and insulation medium, including the three contactors for switching-on and switching-off and to-ground, and is characteristic in its small volume, its convenient installation and operation and its the great adaptability with surroundings.

RLS-12/24/36 of an indoor high-voltage SF6 load switch and RLS-12/24/36D of SF6 load switch plus fuse combination can function to protect and control the electric equipments for power supply and transformer substations especially being suitable for ring net cabinet, cable branch cabinet and distribution switching substation.

RLS-12/24 /36of an indoor high-voltage SF6 load switch and RLS-12/24/36D load switch plus fuse combination are complied with the standards of GB3804-1990, IEC60256-1,1997, GB16926, IEC60420 etc..

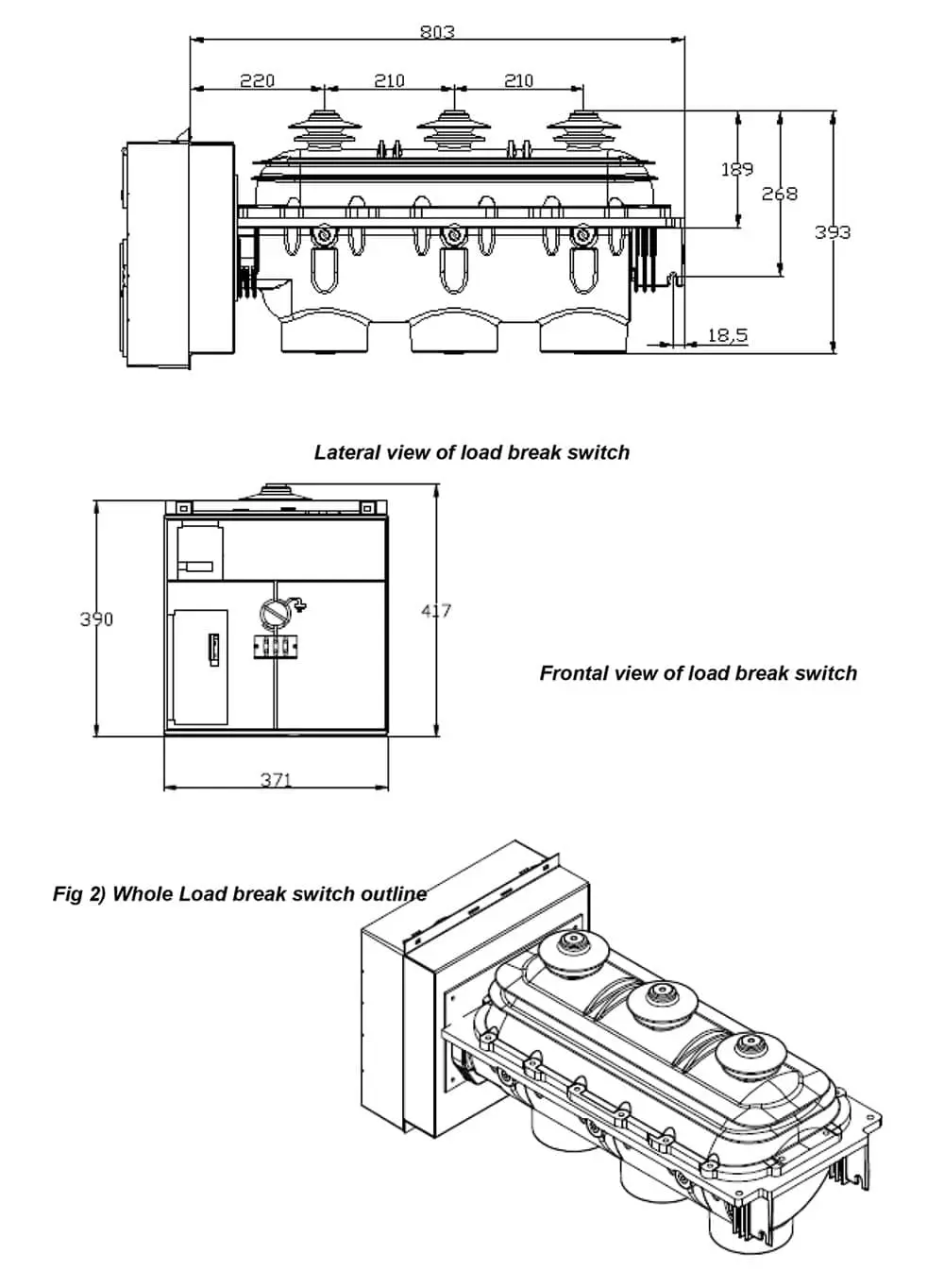

Matching dimension of SF6 load break switch-fuse combination

Fig 1) SF6 load break switch without upper cubicle

Primary loop of RLS type indoor load break switch and its combination is sealed in a epikote casted insulate unit by APG technology, this insulate unit has features of good insulating property, dust and dirts proof, insulate unit contains upper and lower insulate covers, inside charged 0.4bars pressure SF6 gas, the partial siding of lower cover is very thin, it's a protective measure and will burst out in the malfunction, the over pressed gas is released to protect the equipment.

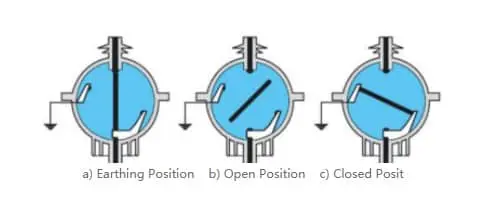

SF6 load break switch and its fuse combination has open, close and earth three working position.

a) Earthing Position b) Open Position c) Closed Posit

RLS-36D load break switch adopts SF6 gas as the medium of arc extinction, when switch on and off, arc occurs and will spin under the magnetic field effect ion by the permanent magnet, cooled by the SF6 gas and extricated finally. This indoor SF6 load break switch and its fuse combination works with spring type operating

mechanisms A and K,RLS-24 load break switch equipped with the K spring operating mechanism is applied as the incoming control unit, while that equipped with A mechanism is applied as the outgoing protective unit and transformer unit.

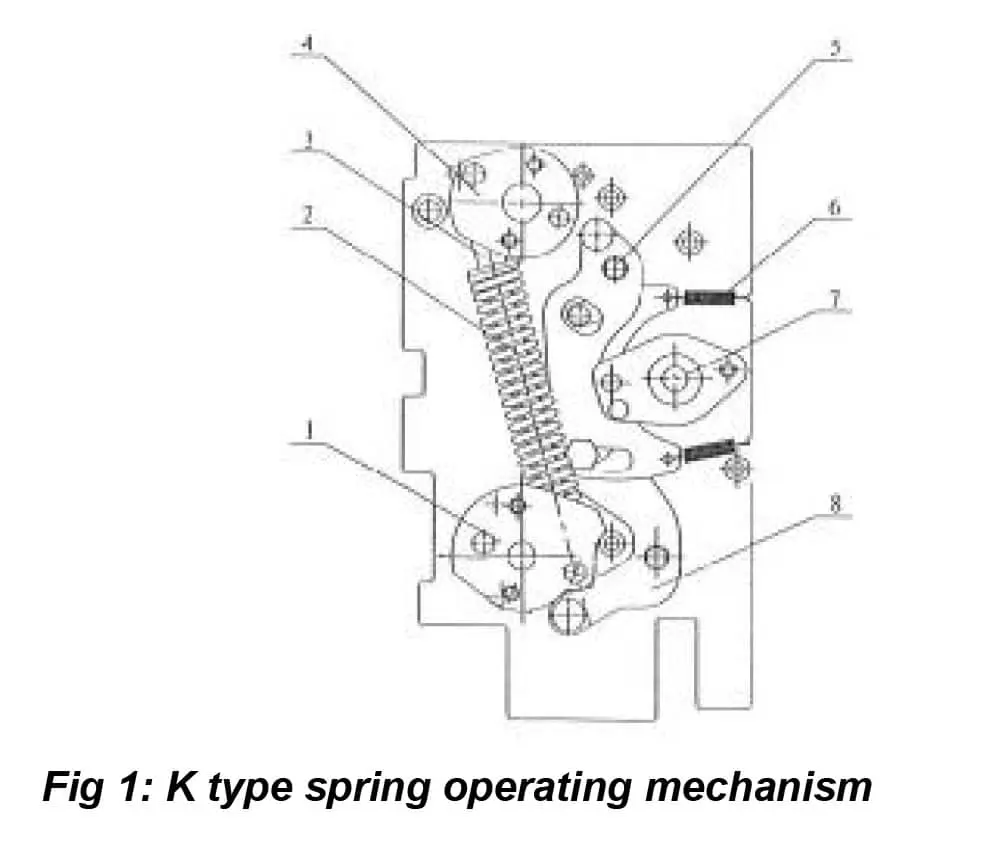

1) "K" Type Spring Operating Mechanism

Working principle of K type spring operating mechanism is spring press and release( see fig 1. it's in off position)

A) Earthing operation

Driven by the handle, upper crank arm 4 rotates and presses spring 2 to store energy, when the max energy reached continue rotate the crank arm, the energy storage spring starts to release energy and drive the upper trigger, enables the connecting bar to drive the crank arm, crank arm rotates and drives the moving contactor for earthing.

B) Switch on operation

Driven by the handle, lower crank arm 1 rotates, presses spring 2 to store energy, when the energy released, it drives the trigger 8, enables connecting bar to drive the crank arm, crank arm rotates and drives the moving contactor and load break switch turns on.

C) Switch off operation

Rotate the main shaft crank arm counterclockwise by the handle, release the energy storage spring and the load break switch turns off.

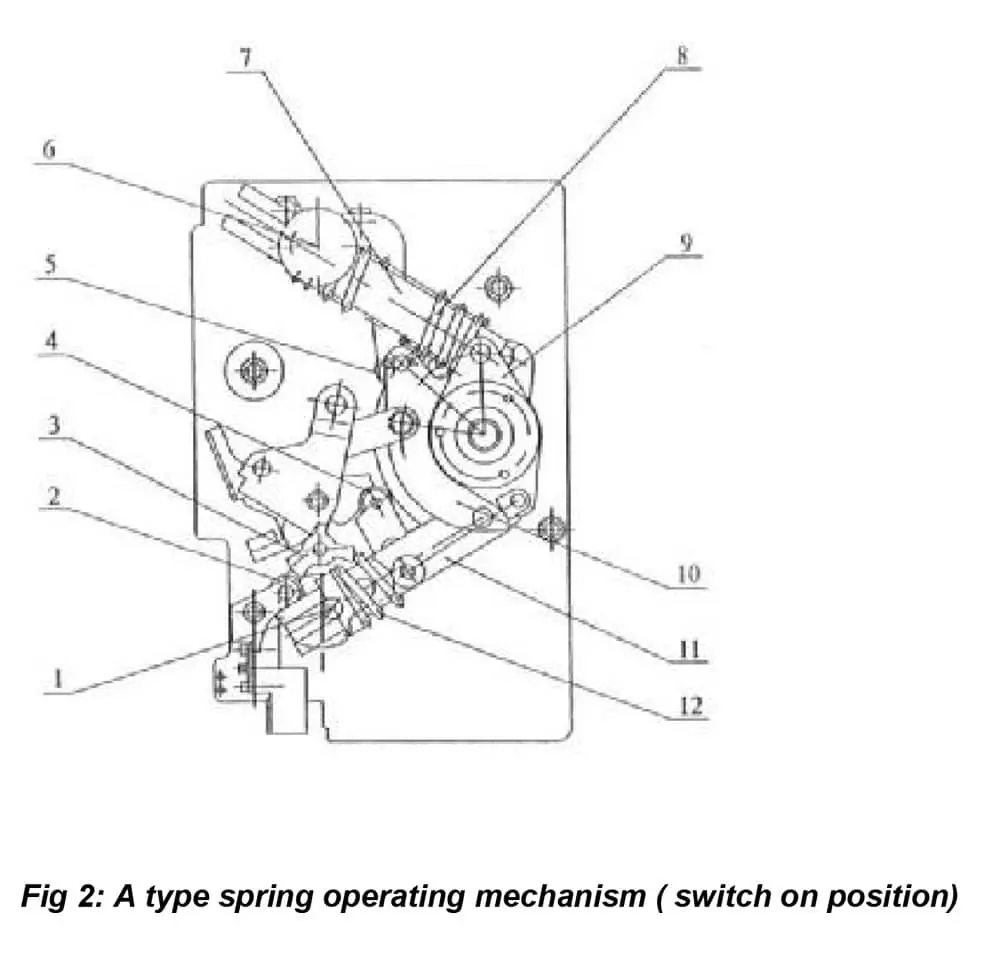

2) "A" Type Spring Mechanism

Working principle of A type mechanism is same as K type, in addition, it has fuse striker trip function. For A type mechanism, electromagnetic trip is also available on customers requirement.(see fig 2)

A) Switch on operation

Driven by the handle, lower crank arm 1 rotates to presse switch on spring 12 and switch off spring 8 at the same time, to provide sufficient energy required by switching off. when the lower crank arm 1 buckles the pin and drives trigger to move, it makes the lower roller wheel tripd, and release the switch on spring and load break switch turns on.

B) Switch off operation

Press the switch off button or push the trip pin 2 by the fuse striker, release the spring and load switch turns off.

C) Earthing operation

Earthing operation of A type mechanism is same as that of K type.

3) K type and A type operating mechanism can be operated manually or motorized on request.

Notice: only when the load break turns off, can turning on and earthing operation be

1-lower crank arm

2-energy storage spring

3-guider bar

4-upper crank arm

5-upper trigger

6-pull spring

7-main shaft crank arm

8-lower trigger

1-lower crankshaft

2-trip pin

3-cam

4-lower roller wheel

5-upper roller wheel

6-upper crankshaft

7-upper guider bar

8-switch off spring

9-energy storage crank arm

10-main shaft crank arm

11-lower guider bar

12-switch on spring